Waste-to-Energy (WtE), waste incineration with energy recovery, plays an important two fold role in waste management and energy systems. This article illustrates how WtE creates warmth from waste and turns ashes into resources.

Marta Gurin

Technical & Scientific

Officer Confederation of

European Waste-to-

Energy Plants (CEWEP)

“Living well, within the limits of our planet” is the subheading of the 7th Environment Action Programme [5], which is the guiding document for the European environmental policy until 2020. The second out of its three key objectives is to turn Europe into a resource efficient, green, competitive and low-carbon economy.

In a recent communication entitled “Towards a circular economy: A zero waste programme for Europe” [6], accompanied by a legislative proposal for the review of the waste targets, the European Commission further proposes a framework for reaching a resource efficient economythrough addressing waste management activities.

After giving a general outlook on Waste-to-Energy (WtE) in Europe, that is waste incineration with energy recovery, this article will present two good practice examples showing how in particular the treatment of residual waste in WtE plants fits into European resource efficiency strategy. This article will therefore present WtE as a vital link for a circular economy.

SPIS TREŚCI

Outlook on WtE in Europe

Instead of being landfilled, the residual household and similar industrial and commercial waste that is not suitable for recycling is treated in WtE plants. It is a hygienic method of treating waste and reducing its volume by about 90%. At the same time the energy contained in the waste is recovered in the form of steam, heat or electricity depending on local demand. These basic facts show the important two fold role of WtE in waste management and energy systems.

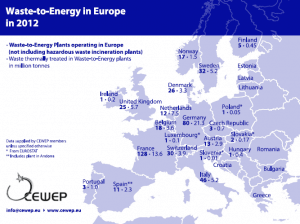

Fig.1 WtE in Europe in 2012, SOURCE: CEWEP

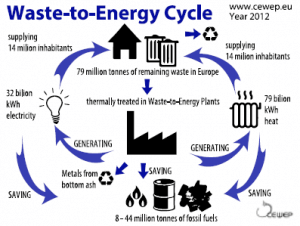

In 2012, 456 WtE plants across Europe (EU28 + Norway and Switzerland) recovered energy, and prevented about 79 million tonnes of residual waste from being landfilled. About 50% of the energy produced by WtE plants comes from biodegradable biomass [7], providing low-carbon input into the energy system. This also helps to achieve the European Union’s (EU) policy for renewable energy sources to cover 20% of the whole energy consumption by 2020. The energy available from the amount of waste thermally treated in WtE plants in 2012 represents 32 billion kWh of electricity and 79 billion kWh heat. This is enough to supply 14 million inhabitants with low-carbon electricity and 14 million inhabitants with low-carbon heat. This energy is locally available and reduces import of fossil fuels. Furthermore, between 8 and 44 million tonnes of fossil fuels (gas, oil, hard coal and lignite) can be substituted annually, which would otherwise emit 22-43 million tonnes of CO2.

Considering that in 2012 the EU28 imported 106 billion m3 of natural gas from Russia [4], it is worth noting that the energy content of the waste treated by WtE plants in 2012 equals to 19% of Russian gas imports in 2012. And in 2020 it could reach even 33% of Russian gas imports. WtE replaces fossil fuels, ensures security of supply (a locally available, base load energy source), and provides cost-effective and renewable energy.

Apart from input to the energy system, WtE plays an important role in diverting waste from landfills. In doing so it goes hand in hand with recycling. It also ensures a high quality recycling by treating all residual waste that is not suitable to be recycled. “Recycling of many waste materials certainly provides valuable products but also – and inevitably if the aim is ‘clean cycles’ – it produces recycling residues that are unsuitable for further use and that have to be disposed of in sinks. Thus, “landfilling and incineration are as essential as prevention and recycling, and they depend upon each other to get the job done” [1].

New recycled materials depend on the quality of the sorted waste. It is worth noting that there are some materials which are too dirty or too contaminated containing, for example, flame retardants or heavy metals and mixed materials that are too difficult or too expensive to sort. In addition, materials degrade after repeated recycling (in particular, plastic and paper fibers lose their properties) and the sorting activity produces residues that need to be treated. “Recycling does have limits and is a means to higher level targets – not a goal in itself” [10].

Fig.2 WtE cycle in 2012, SOURCE: CEWEP.

Fig.2 WtE cycle in 2012, SOURCE: CEWEP.

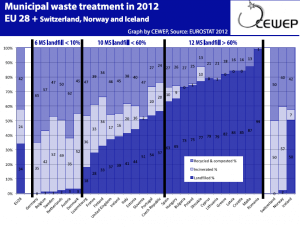

If high quality recycling is not possible, the waste should be turned into energy, rather than being landfilled. Even countries with the highest recycling rates in Europe, Germany, Belgium, Sweden, Netherlands, Austria and Denmark that landfill less than 10% and recycle above 50% of their municipal waste depend on WtE to treat the remaining waste that is not suitable for recycling. All these countries have introduced landfill bans in order to recycle as much as possible and to turn into energy the waste which is not suitable for recycling.

WtE diverts waste from landfilling, reduces volume and sanitises waste, provides final sink for pollutants and keeps them out of the recycling loop.

Warmth from Waste in Denmark

In many European cities WtE plants are connected to the local district heating networks providing low cost and sustainable energy. For example, in Paris, Brescia, Copenhagen and Malmö sustainable energy from waste covers more than 50% of heat demand [2].

In Europe, recovered energy from waste for district heating systems represents 50 TWh per year, i.e. around 10% of the total heat delivered through district heating systems. The Study Heat Roadmap Europe 2050 [8] suggests that the potential for using heat from waste equals to 200 TWh per year by 2050.

Fig.3 Municipal waste management in Europe in 2012, SOURCE: CEWEP based on Eurostat 2012.

Fig.3 Municipal waste management in Europe in 2012, SOURCE: CEWEP based on Eurostat 2012.

A good example of the synergy between WtE and district heating can be found in Denmark. Since the oil crisis in the 1970’s great efforts have been made in Denmark to establish large district heating transmission networks in order to reduce the dependence on oil. WtE is a part of this policy as waste is a locally sourced fuel that, in addition to reducing the use of fossil fuels, contributes to increasing fuel independence.

One of the world’s largest district heating networks is the Copenhagen network that stretches more than 50 km from east to west. Three WtE plants supply heat to the same network and more than 50% of the total district heating in the Greater Copenhagen area is generated by waste.

Danish success factors in using warmth from waste include:

- an extensive landfill ban on combustible waste,

- the operation of WtE plants in the Combined Heat and Power (CHP) mode,

- wide spread district heating systems,

- a high utilisation of energy and high energy efficiency,

and - a high level of public acceptance.

From Ashes to Resources in the Netherlands

The bottom ash is the residue from the combustion process in the WtE plants. Even if the waste was sorted before hand, some metals are still found in it. Both ferrous metals and non-ferrous metals can be taken out of the bottom ash and recycled e.g. for aluminium castings for the automotive industry. After the metals are taken out, the rest of the ashes – (mineral fraction), which are like gravel or sand, are stored for a period before being used as secondary aggregates in construction, mainly as a foundation material (roads, parkings, etc.) [3]. The composition of bottom ash varies depending on the input of a WtE plant. On average in 1000 kg of bottom ash mineral fraction represents 80-85%, ferrous metals 10-15% and non-ferrous metals 3-5%.

The WtE plants contribute to achieving a recycling society and to improving Europe’s resource efficiency by using unavoidable waste as a valuable resource wherever possible. Recycling of bottom ash is part of the resource efficiency strategy.

A good example of a resource efficient use of bottom ashes can be found in the Netherlands. Dutch WtE plants are very efficient in the recovery of energy from waste, and currently deliver almost 12% of all sustainable energy produced in the Netherlands [11]. This is however only a part of their input to the resource efficient economy. In addition, the use of aggregates from bottom ash and the separation of metals plays also a very important role. The Dutch law [9] established a strict framework for the use of aggregates from bottom ash as a construction material. For over 20 years around 20 million tonnes were used as a foundation material for roads [12].

In 2013, in the Netherlands, around 7.5 million tonnes of residual waste was thermally treated in WtE plants. Around 1.7 million tonnes of bottom ash were turned into mineral fraction. Although waste is separately collected, there are still some metals left that are recovered from bottom ash. In 2013 around 116.2 tonnes of ferrous metals and 27.1 tonnes of non-ferrous metals were recovered from bottom ash and put to further use [13].

Conclusions

The Danish and Dutch examples can be used in countries where the integrated waste management system is currently being developed. In the main Polish cities district heating networks exist and most of the waste is still landfilled. As a result the energy and material potential of this waste is lost. Thus, it is important to implement in Poland an integrated approach in the construction of the waste management system that would properly take into account the environmental, energy and resource aspects.

If high quality recycling is not possible, the waste should be turned into energy, rather than being landfilled

Such a sustainable approach was described as follows by Prof. P.H. Brunner: “The two main goals of waste management are protection of humans and the environment, and conservation of resources such as materials, energy, and space. For sustainable waste management, a third goal is to manage waste materials in a way that does not leave any burden for neighbours and future generations (‘no export of waste related problems in space and time’). This is intended to protect future consumers by removing hazardous substances from today’s recycling streams, to release from waste treatment only low emissions that do not impair the environment, and to operate and close landfills that require minimal after-care. The concepts to reach the above goals are manifold, from prevention to recycling, composting, waste-to-energy and landfilling” [1].

CEWEP (Confederation of European Waste-to-Energy Plants) is the umbrella association of the owners and operators of Waste-to-Energy Plants (waste incineration with energy recovery) across Europe. CEWEP’s members are committed to ensuring high environmental standards, achieving low emissions and maintaining state of the art energy production from waste that is not suitable for sustainable recycling (e.g. too polluted or material is degraded after several times of recycling).

References :

- Brunner P.H., Cycles, spirals and linear flows, Waste Management and Research 2013 31:1, www.wmr.sagepub.com/content/31/10_suppl/1.citation (16.12.2014).

- CEWEP, ESWET, EHP, DHC+, Warmth from Waste: A Win-Win Synergy, April 2014, www.cewep.eu/information/energyclimate/warmthfromwaste/1115.Warmth_from_Waste_A_Win-Win_Synergy.html (16.12.2014).

- CEWEP, Environmentally sound use of bottom ash, www.cewep.eu/information/publicationsandstudies/statements/ceweppublications/m_722 (16.12.2014).

- Eurostat 2012.

- European Commission, DECISION 1386/2013/EU of 20.11.2013 on a General Union Environment Action Programme to 2020 ‘Living well, within the limits of our planet’, www.ec.europa.eu/environment/newprg/ (16.12.2014).

- European Commission, Communication COM(2014) 398 final of 2.7.214 “Towards a circular economy: A zero waste programme for Europe”, http://ec.europa.eu/environment/circular-economy/ (16.12.2014).

- European Commission, Directive 2009/28/EC on energy from renewable sources, www.eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32009L0028&from=EN (16.12.2014).

- Heat Roadmap Europe 2050 (Second pre-study for the EU27), May 2013, http://www.heatroadmap.eu/ (16.12.2014).

- Rijkswaterstaat Environment, Soil Quality Decree, www.rwsenvironment.eu/subjects/soil/legislation-and/soil-quality-decree/ (16.12.2014).

- Velis C.A., Brunner P.H., Recycling and resource efficiency: it is time for a change from quantity to quality, Waste Management & Research 2013 31: 539, www.wmr.sagepub.com/content/31/6/539.full.pdf+html (16.12.2014).

- Vereniging Afvalbedrijven, www.wastematters.eu/about-dwma/activities/waste-to-energy/activities-in-the-netherlands.html (16.12.2014).

- Vereniging Afvalbedrijven, www.verenigingafvalbedrijven.nl/afvalmanagement/energie-uit-afval/bodemas-als-grondstof.html (16.12.2014).

- Vereniging Afvalbedrijven, www.verenigingafvalbedrijven.nl/nieuws/nieuwsbericht/reststoffen-verbranding-afval-biomassa-slib-2013.html (16.12.2014).

Logistyka Odzysku 1/2015 (14), str. 24-31